Corn Puff Snacks Production Line

How do they make puffed corn snacks?

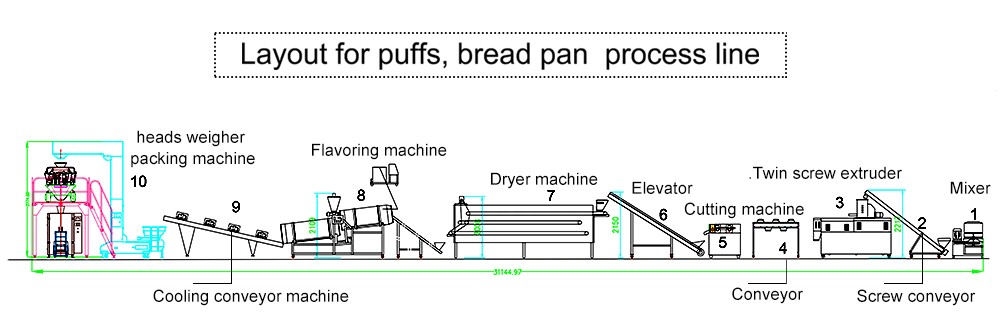

flow chart: mixer → screw conveyor → screw extruder → shaping machine → elevator → oven → seasoning line → packaging machine

Extruded maize snacks are manufactured through extruding moistened maize meal under high pressure and temperature conditions. The puffed product is then fried and usually coated with a savoury flavour such as cheese, chilli, barbeque sauce, sour cream or onion. The flavouring agent is applied in a powder form.

Loyal Snack Machines feature innovative technology developed through years of experience delivering snack food systems around the world.

We have 20 food engineers who have been engaged in the development of snack machinery for a long time, and can provide stable technical support and formulas all year round.

Any popular puffed snack production process can be delivered quickly!

And keep the taste!

| CORN PUFF SNACKS PRODUCTION LINE | |

| NO. | MACHINE OF CORN PUFFED SNACKE MAKING MACHINE |

| 1 | Flour Mixer |

| 2 | Double Screw Extruder |

| 3 | Air Conveyor |

| 4 | Multi-Layers Dryer (Electrical Type) |

| 5 | Multi-Layers Dryer (Gas Type) |

| 6 | Flavoring Machine |

| 7 | Cooling Conveyor |

| 8 | Molds Of Extruder |

| 9 | Control Cabinet Of Extruder |

| 10 | Control Cabinet Of Oven |

- Small scale puffed corn snack making machine

- Shandong China

- Loyal

- Cheetos Making Machine

- Shandong China

- Loyal

- Automatic Cheese Puff Snack Production Line

- Shandong China

- Loyal

- Puffing Snacks Cereal Making Machine

- Shandong,China

- Loyal

- Core Filling Snack Production Line

- Shandong China

- Loyal

- Corn Puff Snacks Making Machine

- Shandong,China

- Loyal