Automatic Crispy Sticks Processing Line

Equipment introduction

Crispy Chips/Bugles/Sticks Process Line is a new technology that replaces traditional rice crackers with twin-screw extrusion technology. The automatic fried sticks production line integrates mixing, maturation, expansion and molding, and does not require a boiler. The fried snacks production process is simplified, efficient, environmentally friendly and low-carbon. The raw material can be a single material such as rice flour, corn flour, flour, etc., or a mixture thereof. The shape can be changed only by changing the mold, forming machine and cutting machine: strip, corrugated square sheet, diamond sheet, wave sheet, pillow shape, horn shape, etc. The produced rice crackers, salad bars, salad chips, sharp corner crisps, wonderful crisp corners and other foods have various colors, and the taste is crisp and not greasy.

Crispy Chips/Bugles/Sticks Process Line

Crispy Chips/Bugles/Sticks Process Line

Process/equipment configuration

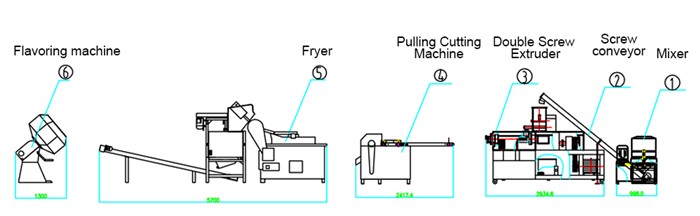

①Flour mixer→②Screw conveyor→③Double screw extruder→④ Pulling cutting machine→⑤Automatic fryer→⑥ Flavoring machine

Product show

Product show

Performance characteristics

Performance characteristics

The commercial fried sticks snacks making machine is a new technology that replaces traditional rice crackers with twin-screw extrusion technology.

Full automatic crispy fried dough snacks production line integrates mixing, maturation, expansion and forming, and does not require a boiler. The fried dough sticks food production process is simplified, efficient, environmentally friendly and low-carbon.

The raw material can be a single material such as rice flour, corn flour, flour, etc., or a mixture.

Product advantages

Product advantages

1. The design of the whole fried crispy dough food making machine is compact and reasonable, and the operation is convenient

2. International brand electrical devices, big brands, and reliable.